News

The HFB-System PRE represents the latest development stage of the HFB-System. With this development an important milestone towards full automation and reproducibility for our pick and place systems was achieved.In this configuration, the positioning of the components is exclusively motorized and controlled by the well-known Pattern Recognition System from Cognex. Depending on the presentation, the components to be assembled can be processed individually or in series.

- Fully automated

- Small footprint

- Immediately productive

- Versatile use

- Cycle time <5 sec.

Events

- no dates available

HFB-System PRE

Versatile automatic Die Bonder-System with granite table on steel frame for changing lot sizes.

Highlights:

- Fully automated

- Small footprint

- Immediately productive

- Versatile use

- Cycle time <5 sec.

The HFB-System PRE represents the latest development stage of the HFB-System. With this development an important milestone towards full automation and reproducibility for our pick and place systems was achieved.

In this configuration, the positioning of the components is exclusively motorized and controlled by the well-known Pattern Recognition System from Cognex. Depending on the presentation, the components to be assembled can be processed individually or in series.

Applications

- Die bonding

- Flip Chip Bonding

- CoS (chip on Submount)

- MEMS / MOEMS assembly

- sensor assembly

- assembly of optical components (photo diodes, laser diodes)

- assembly of lenses and lens arrays

- Laser bar bonding

- assembly of mechanical components

- sorting of components

- assembly of medical parts

Technologies

- thermo-compression bonding (eutectic bonding, Au/Au bonding, Au/Sn bonding)

- ultrasonic - or thermosonic bonding

- adhesive bonding

- dispensing

- dipping

- stamping

- UV curing

Options

- HMTPA (high magnified two point alignment)

- different light sources

- dispensing / stamping

- UV-curing

- heated pick-up tools

- heating plates with and w/o vacuum structure

- Coplanarity tools

- process gas chamber

- process gas suction

- support plate with vacuum

- input-/output station with or without vacuum

- up to four cameras

- height adjustable bond stage

Technical specifications

- granite table with x, y and theta stage on steel frame

- beam splitter optics

- freely adjustable assembly process

- bond force: 10 - 500cN

- positioning accuracy: 1 micron

- maximum component size 25mm x 25mm

- maximum substrate size 150mm x 200mm

- foot print: 1200mm x 800mm x 1400mm

Downloads

coming soon

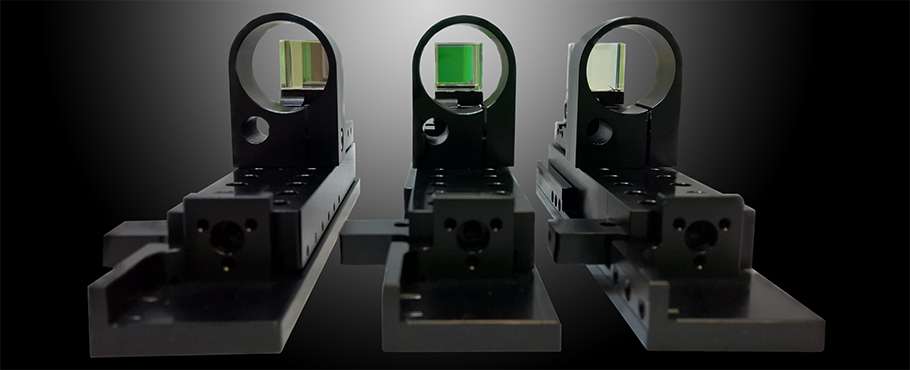

H-System - Die Bonder platform

Semi-automatic Die Bonder-System in overhead gantry arrangement with integrated beam splitter optics for accurate alignment.

Highlights:

- Beam splitter optics

- Second z - axis

- HMTPA (high magnified two point alignment)

- Free programmable automated bond process

- Compact design

- Cycle time <5 sec.

The H-system is a versatile pick-and-place system in overhead gantry arrangement with integrated beam splitter optics. This arrangement ensures a maximum working range by minimal footprint as a desktop device. The integrated beam splitter optics for real time-image overlays allows the operator an intuitive and accurate alignment of component and substrate by means of micrometer screws. The programming of the Z-axis for different bond altitudes guarantees a reproducible connecting process. A second Z-axis can be used for load or unload of single or bonded devices, dispensing, dipping or stamping without tool exchange. Integrated heating plates, heated pick up tools or dispenser support the respective bond process. The H-system supports all topical and future connecting technologies and applications in the area of micro systems technology.

Applications

- Die Bonding

- Flip Chip Bonding

- CoS (chip on Submount)

- MEMS / MOEMS assembly

- sensor assembly

- assembly of optical components (photo diodes, laser diodes)

- assembly of lenses and lens arrays

- Laser bar bonding

- assembly of mechanical components

- sorting of components

- assembly of medical parts

Technologies

- thermo-compression bonding (eutectic bonding, Au/Au bonding, Au/Sn bonding)

- ultrasonic - or thermosonic bonding

- adhesive bonding

- dispensing

- dipping

- stamping

- UV curing

Options

- HMTPA (high magnified two point alignment)

- different light sources

- dispensing / stamping

- UV-curing

- heated pick up tools

- heating plates with and w/o vacuum structure

- Coplanarity tools

- process gas chamber

- process gas suction

- support plate with vacuum

- input-/output station with or without vacuum

- HD inspection camera

Technical specifications

- Overhead gantry arrangement

- beam splitter optics

- HD camera with optical zoom

- fully programmable bond process

- micrometer screws for x- and y-axis

- height adjustable bond stage

- bond force: 10 - 500cN

- positioning accuracy: 5 micron

- maximum component size:

25 mm x 25 mm - maximum substrate size:

300 mm x 300 mm - working area:

300 mm x 240 mm

Downloads

HFB-System High Flexible Die Bonder System

Semi-automatic Die Bonder-System in rigid granite frame arrangement with a high bond force capability, second z - axis and a beam splitter optics for accurate alignment.

Highlights:

- Bond force up to 1000N

- Second z - axis

- HMTPA (high magnified two point alignment)

- Free pogrammable automated bond process

- Network ready (RDS)

- Cycle time <5 sec.

The HFB-System is a versatile Die Bonder-System designed for micro assembly applications like diffusion bonding or high contact density flip chip bonding. With the integrated dual imaging optics in combination with the programmable Z-axis this system is well suited for reproducible bonding of electronic and opto-electronic components. A physically generated overlay live image allows the operator in combination with a user friendly program interface to intuitively perform the component alignment and bonding. A second Z-axis can be used for load or unload of single or bonded devices, dispensing, dipping or stamping without tool exchange. This arrangement guarantees a maximum of stability at high bond forces as well as a maximum working range using minimal footprint. Available options such as different heating plates, heated pick up tools, ultrasonic module or dispenser further extend the usability of the system. The HFB-system supports all topical and future connecting technologies and applications in the area of micro systems technology.

Applications

- sinter / diffusion bonding

- high contact density Flip Chip Bonding

- CoS (chip on Submount)

- MEMS / MOEMS assembly

- sensor assembly

- assembly of optical components (photo diodes, laser diodes)

- assembly of lenses and lens arrays

- laserbar bonding

- wafer bonding

- assembly of mechanical components

- sorting of components

- assembly of medical parts

Technologies

- thermo-compression bonding (eutectic bonding, Au/Au bonding, Au/Sn bonding, Cu/Cu bonding)

- ultrasonic - or thermosonic bonding

- adhesive bonding

- dispensing

- dipping

- stamping

- UV curing

Options

- HMTPA (high magnified two point alignment)

- different light sources

- ultrasonic module

- dispensing / stamping

- UV-curing

- heated pick-up tools

- heating plates with and w/o vacuum structure

- Coplanarity tools

- process gas chamber

- process gas suction

- support plate with vacuum

- input-/output station with or without vacuum

- HD inspection camera

Technical specifications

- rigid granite frame arrangement

- beam splitter optics

- fully programmable bond process

- air cushion table with micrometer screws for x- and y-axis

- levelable and height adjustable bond stage

- HD camera with optical zoom

- bond force: 0.1 - 1000N

- positioning accuracy: 3 micron

- maximum component size 25mm x 25mm

- maximum substrate size 175mm x 175mm

- working area: 175mm x 150mm

- open frame for process gas suction

Downloads

Operating System

Intuitive operating system for continuous process control and traceability with connection to your data system.

Highlights:

- freely programmable machine processes

- recipe based management of process parameters

- storage of process parameters and component data

- remote service and control via LAN

- flexible data import and export via ftp

- component tracking

- different operator level for repeatable work flow

- same software on all Paroteq systems

Pick up tools

Component-saving placement with coplanarity adjustment and dynamic heater.

For the assembly of various components in the fields of mechanics, electronics and optoelectronics Paroteq provides assembly tools which are optimally adapted to the particular application. These tools use passive coplanarity adjustment to ensure a coplanar assembly.

Technical specifications

- up to 50k/S

- up to 450 °C

- coplanarity adjustment for component-saving placement

- thermocouple type K or PT100

- any vacuum structure

- shaft diameter: 3 - 6 mm

Applications

- Die bonding

- Laser bar bonding

- MEMS / MOEMS assembly

- Sensor assembly

- Assembly of optical components

Technologies

- Thermo-compression bonding (eutectic bonding, Au/Au bonding, Au/Sn bonding

- Adhesive bonding

Dynamic heaters

Dynamic heaters for micro assembly

For bonding of the mounted components Paroteq offers heaters for pick-up tools and heating plates which ensure a reproducible compliance of particular bonding parameters by their dynamic heating characteristics. Moreover their low thermal mass guarantees a reduction of the heat input into the assembly system.

Technical specifications

- up to 50k/S

- up to 450 °C

- active cooling

- 10mm height adjustment

- thermocouple type K or PT100

- any vacuum structure

Options

- shielding gas chamber for heating plate

- flow meter for shielding gas chamber 1-10 LPM

- mechanical component clamping

- vacuum clamping

- additional vacuum for flexible substrates

- temperature profiles with ramps

Applications

- Die Bonding

- MEMS / MOEMS assembly

- Sensor assembly

- Assembly of optical components

Technologies

- Thermo-compression bonding (Eutectic bonding, Au/Au bonding, Au/Sn bonding)

- Adhesive bonding

Quality assurance

Universally applicable glass scales for quality assurance and adjustment of manual and automatical, imaging microsystems with a resolution of 0,5 - 10 µm

Testing and adjusting

Our glass scales allow precise statements about the assembly accuracy of pick-and-place systems. Moreover the glass scales can be used to check the accuracy of image processing systems (PRS - pattern recognition system) on automatic assembly systems.Technical specifications

- 6 mm x 8 mm x 0,5 mm (bottom)

- 5 mm x 4 mm x 0,5 mm (top)

- 0,5 - 10 µm resolution on one scale

- opaque chrome structure in transparent environment

Applications

- for testing and adjustment of the positioning accuracy of micro systems ( e.g. pick-and-place machines for chip adjustment)

- checking of positioning systems with image processing ( PRS, pattern recognition system)

- Machine capability studies (CMK)

Accessories

- vacuum pick-up tool

- vacuum suction plate

Entwicklungsdienstleistungen

Paroteq unterstützt Sie bei der Entwicklung und Konstruktion von neuen Produkten.

Highlights:

- 3D-Modellierung (Solid Works)

- Dokumentation 2D-CAD- Montagezeichnungen (Solid Works)

- SPS Programmierung (Omron)

- Visualisierung (Omron)

What we do

Paroteq GmbH is an innovative developer of high quality handling and automation solutions from the area of micro assembly.We provide our customers with individual and application-oriented systems and tools for precision processes such as flip chip bonding or die bonding. As a company with international expertise in the field of micro assembly we develop and produce semiautomatic positioning and bond systems, modules for optical alignment, heating systems for thermo compression bonding as well as a wide range of pick-up tools for component handling in micro system technology.

As a result of combining our modules and subsystems we create individual bond systems, which can be used for engineering, prototype construction and production in the fields of electronics, optoelectronics, medical and micro systems technology.

Career

Paroteq ist ein Unternehmen aus dem Bereich der Entwicklung und Fertigung von Sondermaschinen für Mikromontage -Applikationen mit Sitz in Hennigsdorf bei Berlin. Zu unseren Leistungen gehören der gesamte Entwicklungsprozess der Geräte von der Entwicklung bis zur Montage und die kunden- und anwendungsspezifische Anpassung der Geräte sowie die Entwicklung und den Verkauf von hochwertigem Zubehörequipment.Zur Verstärkung unseres Teams bieten wir zum nächstmöglichen Zeitpunkt qualifizierte und zuverlässige Mitarbeiter in den Positionen:

Studentischer Mitarbeiter (m/w) aus dem Bereich Mechatronik

- Gute Kenntnisse im Umgang mit SolidWorks

- Kenntnise der SPS-Programmierung

- Gute handwerkliche Fähigkeiten für Herstellung und Montage der Geräte

- Grundkenntnisse der Elektrotechnik

- Gute Englisch-Kenntnisse

- Strukturierte Arbeitsweise, Aufgeschlossenheit und ein freundliches Wesen

Industriemechaniker (m/w)

Was Sie erwartet:

- Herstellen von Produktionsanlagen der Mikrosystemtechnik

- Baugruppenmontage, Verdrahtung und Inbetriebnahme

- Einrichten und Einstellen von Maschinen und Systemen

- Durchführen von Qualitätskontrollen

- Fräsen, Drehen, Bohren

Was Sie mitbringen sollten:

- Abgeschlossene Berufsausbildung als Industriemechaniker (m/w)

- Strukturierte, selbstätige Arbeitsweise, Aufgeschlossenheit und ein freundliches Wesen

- Erfahrungen in der Feingerätetechnik wünschenswert, aber nicht zwingend erforderlich

- Freude an der Arbeit im Team

- Ein freundliches und kreatives Arbeitsklima in einem jungen Unternehmen

- Gemeinsame Arbeit an Projekten statt isolierter Beschäftigung

- Flexible Arbeitszeiten (auch an Wochenenden möglich)

- Abwechslungsreiche Tätigkeiten

- Eine angemessene Vergütung

Imprint

disclosures in § 5(1) N0. 1,2 Telemedia ActResponsible for content:

Paroteq GmbH

Represented by:

CEO: Udo Hartwig

Contact:

Walter-Kleinow-Ring 7A

16761 Hennigsdorf (bei Berlin)

Deutschland

Telefon: +49 (0)3302 8982901

E-Mail: info@paroteq.de

http://www.paroteq.de

USt-IdNr.: DE295628812

Handelsregisternr.: HRB.10746 NP

Disclaimer

All due precautions and efforts were taken in the compilation of this website in order to keep the information contained as current, correct and clear as possible. Despite the greatest diligence unintentional misinformation cannot be ruled out. Paroteq therefore refuse any responsibility especially for typing or printig errors and for the exactness, completeness and topicality of the information provided on the website of the company. The information and data provided on the Paroteq website may be altered at any time without prior announcement. They are provided by Paroteq without any obligation and exclude any warranty. As far as the Paroteq website contains links or pointers to a third party website, Paroteq does not accept any responsibility for any information, material or link contained in them. We expressly declare that we do not in any case agree with the contents of linking pages. By visiting the Paroteq website you alone take over any risk of damage to your computer, software or data by viruses or other software which is transferred or activated via the Paroteq website or your visit to it. In no case can Paroteq be held responible for any direct, indirect, special, concomitant or subsequent damage or escaped profit resulting from the use or misuse of information or from incomplete information on the Paroteq website.Privacy

Legal basis

To the extent that we have obtained the data subject's consent for the processing of the personal data, Article 6(1), subparagraph 1a of the GDPR shall apply as the legal basis.If the processing of personal data is necessary for the performance of a contract with the data subject or for pre-contractual measures initiated by the data subject, Article 6(1), subparagraph 1b (DSGVO) serves as the legal basis.

If the data processing is the result of a legal obligation to which we are subject, we invoke Article 6(1) subparagraph 1c of the GDPR as the legal basis.

If the processing of personal data is carried out in order to protect the vital interests of the data subject or another natural person, Article 6(1), subparagraph 1d (GDPR) serves as the legal basis.

If the data processing serves a task in the public interest or is carried out in the exercise of official authority, we invoke Article 6(1) subparagraph 1e of the GDPR.

To the extent that the processing of personal data is necessary to protect the legitimate interests of the controller or a third party - without jeopardizing the interests, fundamental rights or freedoms of the data subject - Article 6(1), subparagraph 1f (DSGVO) shall apply as the legal basis.

Gathering/Processing/Usage of personal data

When you visit our website, we automatically collect and store information in so-called server log files. Your browser automatically transmits this information to our server or to the server of our hosting company. These are:Cookies

We don't use cookies.Contact form

On our website there is the possibility to notify us via a contact form. For contacting us via this form, your contact details in particular are required. As a legal basis, reference is made here to processing for the purpose of contract performance or pre-contractual measures pursuant to Art. 6 (1) lit. b DSGVO. In addition, there may be a legitimate interest to maintain business relationships or to respond to your request for other reasons. In this case, the legal basis for the processing of your data would be Art. 6 (1) lit. f DSGVO. The data will be deleted when we have conclusively answered your inquiry and there are no other storage obligations to the contrary.How to find us

Contact

Paroteq GmbH

Walter-Kleinow-Ring 7A

1. Etage links

16761 Hennigsdorf (near Berlin)

Germany

Walter-Kleinow-Ring 7A

1. Etage links

16761 Hennigsdorf (near Berlin)

Germany

Telephone: +49 (0)3302 8982901

Telefax: +49 (0)3303 5488714

E-Mail: info@paroteq.de

Web: www.paroteq.de

Telefax: +49 (0)3303 5488714

E-Mail: info@paroteq.de

Web: www.paroteq.de

By using this form you agree that your data will be processed and saved !

Key features H-system

- beam splitter optics for precise alignment

- fully programmable Z-axis

- compact design